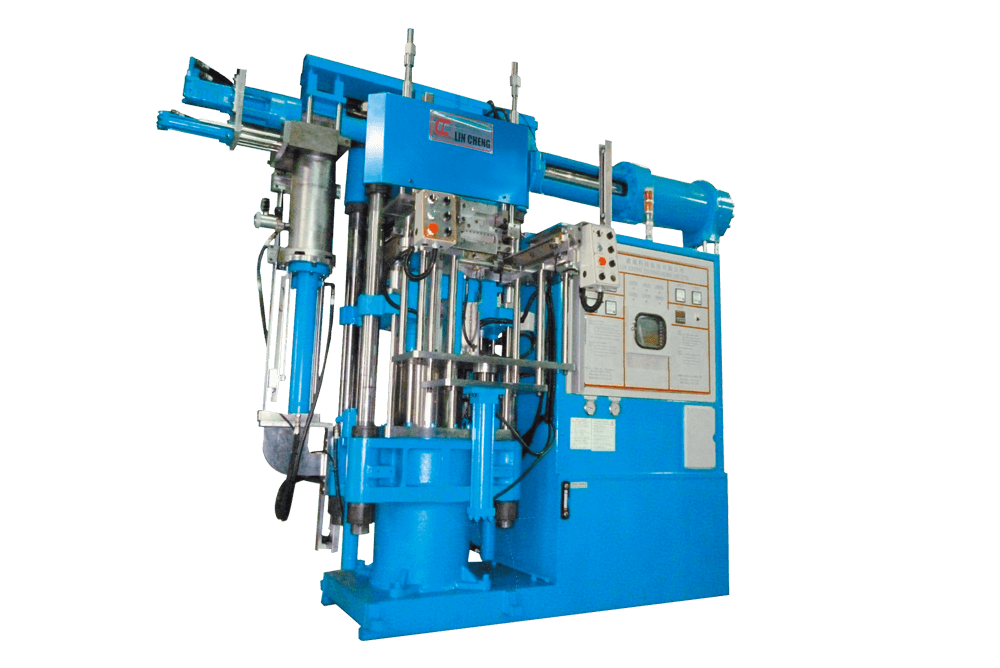

2RT Mold-Open Silicone Injection Molding Machine

ISH-S2/P1-1-3

Home / Our Products / Injection Molding Machine / ISH-S2

Features

-

Mold opening design

The 3RT surpasses the traditional top opening mold that can be used for the triple or four molds with the design of the opening mold and pushing out the mold in the between. The opening mold can be adjusted by the software with separate opening, separate pushing out the mold in between, continuous opening and continuous pushing out the mold in between.

-

Injection volume control

High precision optical ruler is adopted for precisely calculating and controlling.

-

Design of rotary injection board

Special designs for loading/unloading functions are provided. It causes no dead material in the injection nozzle. It is easy to clean the material. It is durable and the quality is stable.

-

Safety design

A high-tech infrared safety electronic sensor and automatic warning system are adopted to monitors the status of machine in order to provide extra protection to ensure the operation safety for operators.

-

Hydraulic system Design

Hydraulic system Designed by proportional pressure and flow ratio, which is steady, quiet and low frequency of malfunction. Two shafts can be operated simultaneously.

2RT Mold-Open Silicone Injection Molding Machine

Specifications

| Diameter of piston (mm) | 225 | 250 | 350 | 400 | 450 | 500 | 560 | 630 | 700 | 900 |

|---|---|---|---|---|---|---|---|---|---|---|

| Clamping force (ton) | 83 | 100 | 200 | 250 | 300 | 400 | 500 | 600 | 800 | 1200 |

| Stroke (mm) | 400 | 400 | 500 | 600 | 600 | 600 | 600 | 600 | 700 | 900 |

| Heating platen (mm) | 350*450 | 400*400 |

503*508 525*560 |

560*560 |

580*600 700*700 |

700*700 | 800*900 | 1000*1100 | 1100*1100 | 1300*1300 |

| Horse (hp) | 10 | 10 | 15 | 20 | 20 | 20 | 20 | 30 | 40 | 50 |

| Injection volume(c.c.) | 500 |

500 900 |

1500 | 2000 |

3000 4000 |

5000 | 7900 | 10000 | 12000 | 18000 |

| Injection Pressure Max(kgf/cm²) | 1650 | 1650 | 1680 | 1700 | 1700 | 1750 | 1778 | 1800 | 1800 | 1900 |